High Accuracy CNC Machining Center

VMC-960/1060/1260

- FEATURE

- EXPLAIN

- SPECIFICATIONS

- Casting are stress relieved and seasoning treated for long term accuracy.

- Three axes slide ways are coated with Turcite B anti-triction material ensuring extremely smooth traverse, and minimum wear on slide ways.

- Automatic lubrication system provides excellent lubrication to all slide ways.

- Driven by high torque, low noise, high stability AC digital servo motors to provide a wide speed range for machining a variety of materials.

- High precision flexible couplings offer the best rigidity and accuracy directly connected the C3 ball screw and AC servo motor.

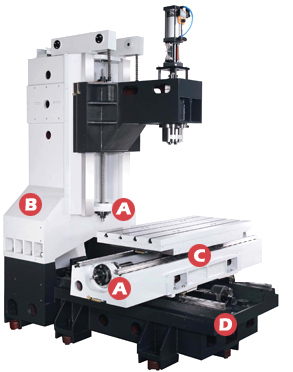

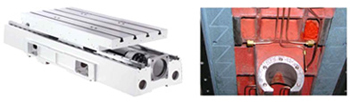

A. Unity Structure on X and Z axis

X axis combined the saddle together for heavy structure and best rigidity. (even if the saddle is more wide, it is not powerful enough without combining together.) Combining together will be more double powerful. Z axis is the same as X axis.

B. Large Span Design for Column

The column is a large span design with an inverted "Y" shape construction for outstanding regidity and stability. Our heavy column design is able to support the headstock for more long time accuracy cutting.

Another one point is the column bottom casting combined both side and connecting together for heavy structure and best rigidity (Special design.) This design is able to avoid if one day the counterweight falling down, it will be useful to prevent the Y axis motor to be damaged.

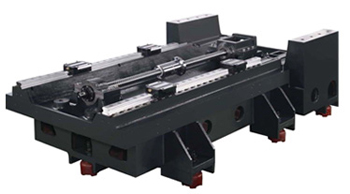

C. Multi-compartments Design

The work table and saddle in multi-compartments design reduce vibration during machining. Special mention the unity casting with the unity casting with the ballscrew nut design (table). It make the machine's structure more rigidity and stability.

D. Large Span Design for Base

The base is large span structure design.

The slideway surface is featured with good support, higher rigidity and more stability.

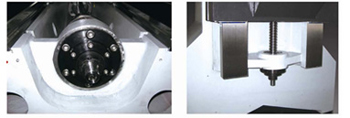

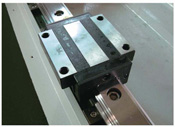

Full Roller Type Linear Guideways (Optional)

Mecatron uses full roller type linear guideways, equip with roller rolling instead of the ball rolling in general, so that same size linear guideways can provide greater rigidity and load capacity, especially for the emphasis on high accuracy, high rigidity and high loading machine needs.

Use of precision three-axis linear guideways, the travel moves fast and smooth, high-speed and high-precision machining for the needs of customers.

(Models: VMC-600/800/960/1060/1260)

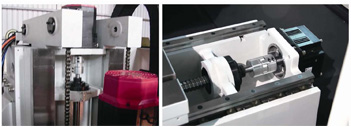

Motor Base Forming One

Motor base, ballscrew support and structure forminh one to be processed. This design allows the motor transmission and ballscrew with the center of the best roundness. So in addition to extend of the life of ballscrew and ballscrew to get the best feed precision and stability. Our servomotors are coupled directly to ballscrews with couplings can effectively absorb the errors caused by installation, such as eccentricity, deflection and clearance between shaft and vibration generated in operation, to protect the servomotor and mechanical functions.

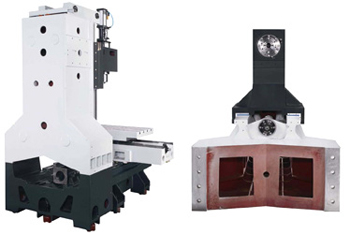

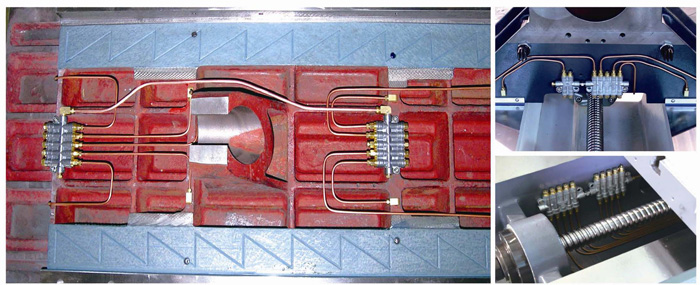

Automatic Lubrication System

Meactron automatic lubrication system distributes lube to all ballscrews and guideways when the machine is running. Lubrication pipes jointer using detective volume distributor, it has the advantage of fixed amount of oil feeling, which is available for each lubrication point of the same lubricant. Each one has detective piston with pressure sensor switch which could send status signals during operation or intermittent time. So if any pipes blockage problems caused by dust, the distributor will send the alarm message to thr PLC and notify the user for emergency measures. So it will not cause mechanical damage. Otherwise, in the absence od oil into pipes, the machine is still running after a few hours, Turcite-B will have to repair due to severe wear and surface may be necessary to re-precision scraping.

Our system used brass pipes, do not worry about the services of fracture problems and Turcite-B damage caused by mechanical precision problems in the future. Brass pipes in the table and saddle design with clear and beautiful.

Turcite-B even in the oil keep on the slideway is on the same design. This design will make it easier for future maintenance operations, and in the saddle on the left of the lubrication protection will allow the entire pipes configuration in the best protected.

Spindle Annular Cooling Jet

There are four jets around the spindle to avoid interference in the machining area caused by conventional coolant nozzles and can improve the cooling effect of the workpiece.

Specifications

| MODEL | UNIT | VMC-960 | VMC-1060 | VMC-1260 | |

|---|---|---|---|---|---|

| Table Specification | Table Surface | mm(Inch) | 550 x 1000 (21.6” x 39.3”) |

550 x 1200 (21.6” x 47”) |

610 x 1400 (24” x 55”) |

| T-Slots | mm | 18 x 4 x 125 | 18 x 4 x 125 | 18 x 5 x 100 | |

| Table Loading | kg | 800 | 1000 | 1200 | |

| Travel Specification | X Axis Longitudinal Travel | mm(Inch) | 900(34.5”) | 1000(39.3”) | 1200(47”) |

| Y Axis Cross Travel | mm(Inch) | 600(24”) | 600(24”) | 600(24”) | |

| Z Axis Vertical Travel | mm(Inch) | 600(24”) | 600(24”) | 600(24”) | |

| Spindle Center to Table Surface | mm(Inch) | 120~720(28”) | 120~720(28”) | 120~720(28”) | |

| Spindle Center to Column Surface | mm(Inch) | 680(27") | 680(27") | 680(27") | |

| Door Opening Width | mm(Inch) | 1200(47”) | 1200(47”) | 1400(55”) | |

| Spindle | Spindle Taper (Standard / Option) |

BT40 | BT40 | BT40 | |

| Spindle Speed (Standard / Option) |

rpm | 8000 / 10000, 12000 | 8000 / 10000, 12000 | 8000 / 10000, 12000 | |

| Rapid Feed Rate | M/min | 30(Linear X. Y) 20(Box Z) | 30(Linear X. Y) 20(Box Z) | 30(Linear X. Y) 20(Box Z) | |

| Cutting Feed Rate | mm/min | 5-10000 | 5-10000 | 5-10000 | |

| Motor | Spindle Motor (Standard / Option) |

HP | 15 | 15 | 15 |

| 3 Axes Motor (X/Y/Z) | kw | 2/2/2 | 2/2/2 | 2/2.5/2 | |

| Miscellaneous | Auto Tool Changer (Standard / Option) |

20/24 | 20/24 | 20/24 | |

| Power Requirement | kw | 25 | 25 | 30 | |

| Air Pressure | Kgs/cm2 | 6 | 6 | 6 | |

| Cooling Motor | HP | 3/4 | 3/4 | 3/4 | |

| Cooling Tank Capacity | L | 300 | 300 | 300 | |

| Machine Weight | kg | 6000 | 6500 | 7000 | |

| Machine Size (L x W x H) | mm | 2800 x 2200 x 2500 | 2800 x 2200 x 2500 | 3200 x 2200 x 2500 | |

| Control | FANUC / MITSUBISHI / SIEMENS | ||||